Blind spots on trucks carrying oversize/overweight loads are a significant road safety concern, posing challenges for drivers and increasing the risk of accidents. This article delves into the causes, consequences, and methods for reducing these blind spots, providing a comprehensive overview of this critical issue.

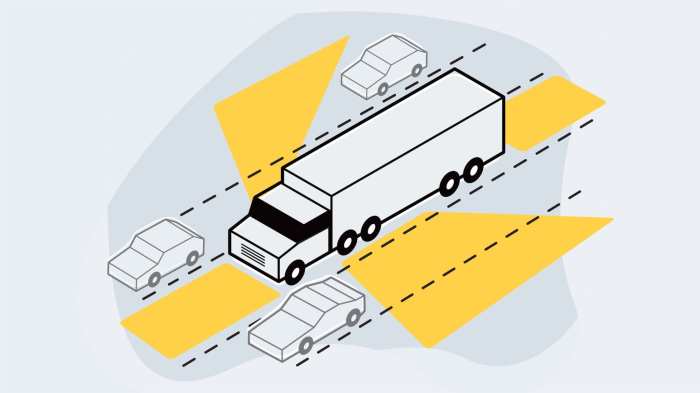

The large size and irregular shape of oversize/overweight loads create extensive blind spots around the truck, obstructing the driver’s view in various directions. These blind spots can lead to hazardous situations, such as the driver being unable to see vehicles or pedestrians in close proximity, potentially resulting in collisions or other incidents.

1. Blind Spots on Trucks Carrying Oversize/Overweight Loads

Trucks carrying oversize/overweight loads create unique and extensive blind spots that pose significant risks to road safety. These blind spots arise due to the sheer size and weight of the cargo, obstructing the driver’s field of vision.

Types of Blind Spots

- Front blind spot:Extends in front of the truck, caused by the height and width of the load.

- Rear blind spot:Behind the truck, resulting from the length and height of the load.

- Side blind spots:Along the sides of the truck, created by the width of the load and the position of the mirrors.

Impact on Visibility

These blind spots severely restrict the driver’s ability to see other vehicles, pedestrians, and obstacles. Drivers may struggle to detect objects directly in front of or behind the truck, particularly at intersections or when changing lanes.

2. Causes of Blind Spots on Trucks Carrying Oversize/Overweight Loads

Several factors contribute to blind spots on trucks carrying oversize/overweight loads:

Size and Shape of the Load

Larger and irregularly shaped loads create more extensive blind spots. High loads can block the driver’s view of traffic signals and overhead obstacles.

Vehicle Design and Driver Positioning

The height of the cab and the positioning of the mirrors can limit the driver’s field of vision. High cabs create larger front blind spots, while poorly positioned mirrors may not adequately cover the side blind spots.

3. Methods for Reducing Blind Spots on Trucks Carrying Oversize/Overweight Loads

Technological advancements and best practices can help mitigate blind spots on trucks:

Innovative Technologies

- Blind spot detection systems:Use sensors to alert drivers to objects in their blind spots.

- Wide-angle mirrors:Provide a wider field of view, reducing side blind spots.

- Cameras and monitors:Offer a real-time view of areas outside the driver’s direct line of sight.

Best Practices

- Proper load placement and securing:Ensure the load is positioned to minimize blind spots.

- Driver training and education:Educate drivers on blind spot awareness and safe driving techniques.

4. Regulations and Enforcement Related to Blind Spots on Trucks Carrying Oversize/Overweight Loads

Regulations govern blind spots on trucks carrying oversize/overweight loads to ensure road safety:

Regulations

Regulations specify maximum load dimensions and require vehicles to have appropriate mirrors and safety devices to minimize blind spots.

Enforcement

Law enforcement agencies enforce these regulations through inspections and penalties for non-compliance.

Penalties

Violations related to blind spots can result in fines, points on the driver’s license, and vehicle impoundment.

5. Case Studies and Real-World Examples

Incidents involving blind spots on trucks carrying oversize/overweight loads highlight the potential consequences:

Case Studies, Blind spots on trucks carrying oversize/overweight loads are

- 2020:A truck carrying an oversized load struck a pedestrian in a crosswalk due to a blind spot.

- 2021:A truck with an overweight load lost control and crashed into a bridge abutment, resulting in multiple injuries.

Lessons Learned

These incidents underscore the need for improved blind spot awareness, proper load securing, and driver training to prevent similar tragedies.

Questions and Answers: Blind Spots On Trucks Carrying Oversize/overweight Loads Are

What are the main causes of blind spots on trucks carrying oversize/overweight loads?

The primary causes include the large size and irregular shape of the load, which can obstruct the driver’s view in various directions, as well as vehicle design and driver positioning.

What are the potential consequences of blind spots on trucks carrying oversize/overweight loads?

Blind spots can lead to hazardous situations, such as the driver being unable to see vehicles or pedestrians in close proximity, potentially resulting in collisions or other incidents.

What are some methods for reducing blind spots on trucks carrying oversize/overweight loads?

Effective methods include utilizing blind spot monitoring systems, wide-angle mirrors, proper load placement and securing techniques, and comprehensive driver training and education programs.

What regulations govern blind spots on trucks carrying oversize/overweight loads?

Various regulations are in place to address blind spots, including requirements for specific mirror configurations, load securement practices, and driver visibility standards.

What are some real-world examples of the impact of blind spots on trucks carrying oversize/overweight loads?

Case studies and incidents highlight the serious consequences of blind spots, such as collisions, injuries, and fatalities involving trucks carrying oversize/overweight loads.